France’s nuclear safety watchdog has found “multiple failure modes” that carry “grave consequences” on crucial safety relief valves on the European Pressurized Reactor (EPR) under construction at the Flamanville nuclear plant situated on the Channel coast in northern France, Mediapart can reveal.

The safety valves play a key role in regulating pressure in the reactor, and their malfunction could cause the meltdown of the reactor.

The findings, by the French Institute for Radiological Protection and Nuclear Safety, the IRSN, which is essentially the technical arm of France’s supreme nuclear safety regulator, the ASN, are contained in a confidential report obtained by Mediapart.

Until now, the 80-page IRSN report, dated February 13th 2015, (which can be read in full here, available in French only) has not been made public.

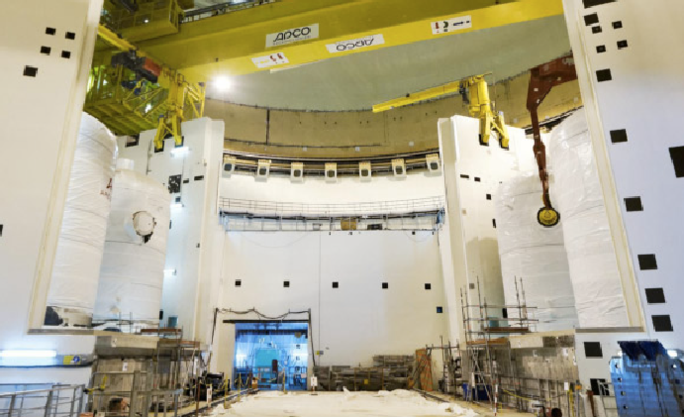

Enlargement : Illustration 1

It is the latest major flaw discovered at the Areva-designed and built EPR at Flamanville, which lies close to the British Channel Islands and about 240 kilometres from the southern English coast. Run by utilities giant EDF, and due to become one of the biggest nuclear power facilities in the world, its construction, which began in 2007, has been blighted by spiralling costs (which are now almost 6 billion euros over budget) and delays – it is now due to enter service in 2017, five years later than originally planned - and a catalogue of safety issues.

In April, it was revealed that excessive amounts of carbon in the steel destined for the top and bottom of the reactor’s vessel – which forms a shell around the reactor - could cause cracks which can subsequently spread with disastrous consequences. The vessel cannot be replaced during the lifespan of the reactor.

Enlargement : Illustration 2

The faulty safety relief valves are situated on the pressurizer, a vessel close to the reactor and which manages the regulation of the high pressure within the primary circuit where water cools the nuclear fuel. In the event that the primary circuit experiences higher than tolerable pressure, the safety valves release vapour from the system to reduce the pressure.

They are an essential part of the safety system on a reactor. The failure of a pilot-operated relief valve in the primary circuit was one of the principal causes of the partial meltdown of a reactor at the Three Mile Island plant in the US in March 1979, and which led to the halting of the US civil nuclear power programme.

In the case of the Three Mile Island accident, the nuclear reactor (one of two at the plant, overheated, leading to a significant rise in pressure within the primary circuit and the subsequent opening of the safety valves. Whereas the valves should have all closed once the pressure had fallen, one of them remained stuck open. As a result, a significant amount of the circuit’s nuclear reactor coolant escaped and the heart of the reactor went into partial meltdown, sending radioactive gases and iodine into the outside air.

At Flamanville, initial tests carried out by the IRSN found that the pilots that operate the safety valves were not functioning correctly. Worse still, they frequently suffered from leaks, which rendered them uncontrollable. The ISRN inspectors reported “unintended opening” of the valves, manufactured by German firm Sempell. Some of the tests by the IRSN could not be completed because the valves became stuck as of the second trial.

The inspectors reported a long list of malfunctions. They include “Risks of fluid leaks”, which refers to the reactor coolant, “opening failure” and “closure failure”. They underlined that “no leak is acceptable” and that the multitude of faults could have “grave consequences”.

The IRSN report questions Areva’s approach to safety at the plant. It noted that the ailing French nuclear firm did not have the means itself to detect all the anomalies recorded by the inspectors, and that it had opted to equip the reactor’s pressurizer with safety valves that were less reliable than those already in place in other French nuclear plants. The IRSN report included the terse notes: “Areva responsible for the conception. No experience by Areva in the conception of safety valves. No involvement of Sempell during the qualifying tests.”

Flamanville reactor vessel 'a technical regression'

Last week, the French government announced that state-controlled Areva’s nuclear reactor business, Areva NP, which designs, builds and services reactors, would be sold off to French utilities giant EDF, its former client which also operates all of France’s 58 nuclear reactors.

The move followed the announcement by Areva in March that it had racked up record losses in 2014 of 4.8 billion euros, which essentially stem from a series of strategic investment blunders, the fall in demand for nuclear reactors following the March 2011 nuclear disaster at the Japanese Fukushima plant, and a catalogue of technical problems encountered by its EPR reactors. Like in Flamanville, the Areva EPR reactor under construction at the Olkiluoto plant in Finland has suffered delays and a tripling of its initial budget.

The announcement on June 4th that EDF would take over Areva’s nuclear core business, reducing what was the world’s largest nuclear technology company to a renewable energies and uranium mining and enriching firm, means that the utilities giant will now become its own supplier for the nuclear plants it runs.

On April 7th, France’s Nuclear Safety Authority, the ASN, to which the IRSN reports, publicly revealed the serious threat of cracks forming on the top and bottom of the Flamanville EPR reactor vessel, due to high carbon concentrations in the steel used. The fault was discovered during tests carried out by Areva in late 2014 on a vessel head similar to that designed for Flamanville, the results of which were subsequently presented to the ASN. This concerns the area of the reactor where atomic fission occurs, and the vessel constitutes the second shield for the confinement of radioactivity.

But the ASN did not reveal all the detail of the problem. For another report by IRSN inspectors, delivered to the ASN in April and obtained by Mediapart, points to further safety failings by Areva.

The IRSN report in April concluded that the Flamanville reactor was less safe than any of the 58 others already operating in France “The IRSN considers that the manufacturing technology chosen for the Flamanville reactor vessel’s head and bottom is a technical regression in comparison to that used by the operating network [of French reactors],” it said. It referred to the chronology of correspondence it engaged in with Areva since the conception of the reactor. In a letter dated from 2002, Areva announced changes in the conception and construction of equipment that disregarded nuclear power construction standards.

The IRSN underlined that problems with the reactor vessel’s casing had already been discovered during early testing of the structure. The IRSN concluded that the programme of tests now being conducted by Areva to remove the flaws of the vessel do not offer a guarantee of the same level of safety as that of the 58 others already in operation.

-------------------------

- The French version of this article can be found here.

English version by Graham Tearse